Best Lighting for Food Processing & Cold Storage Facilities

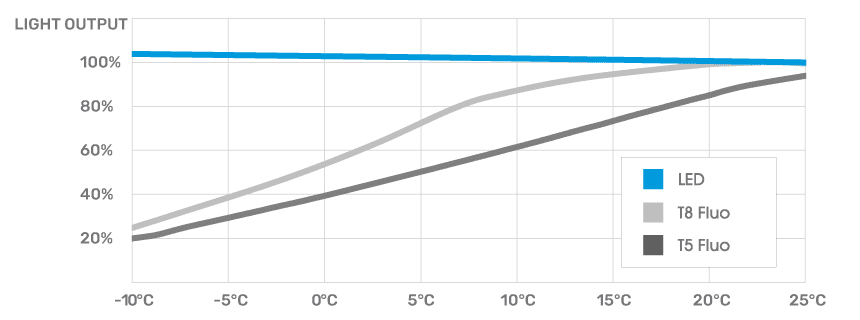

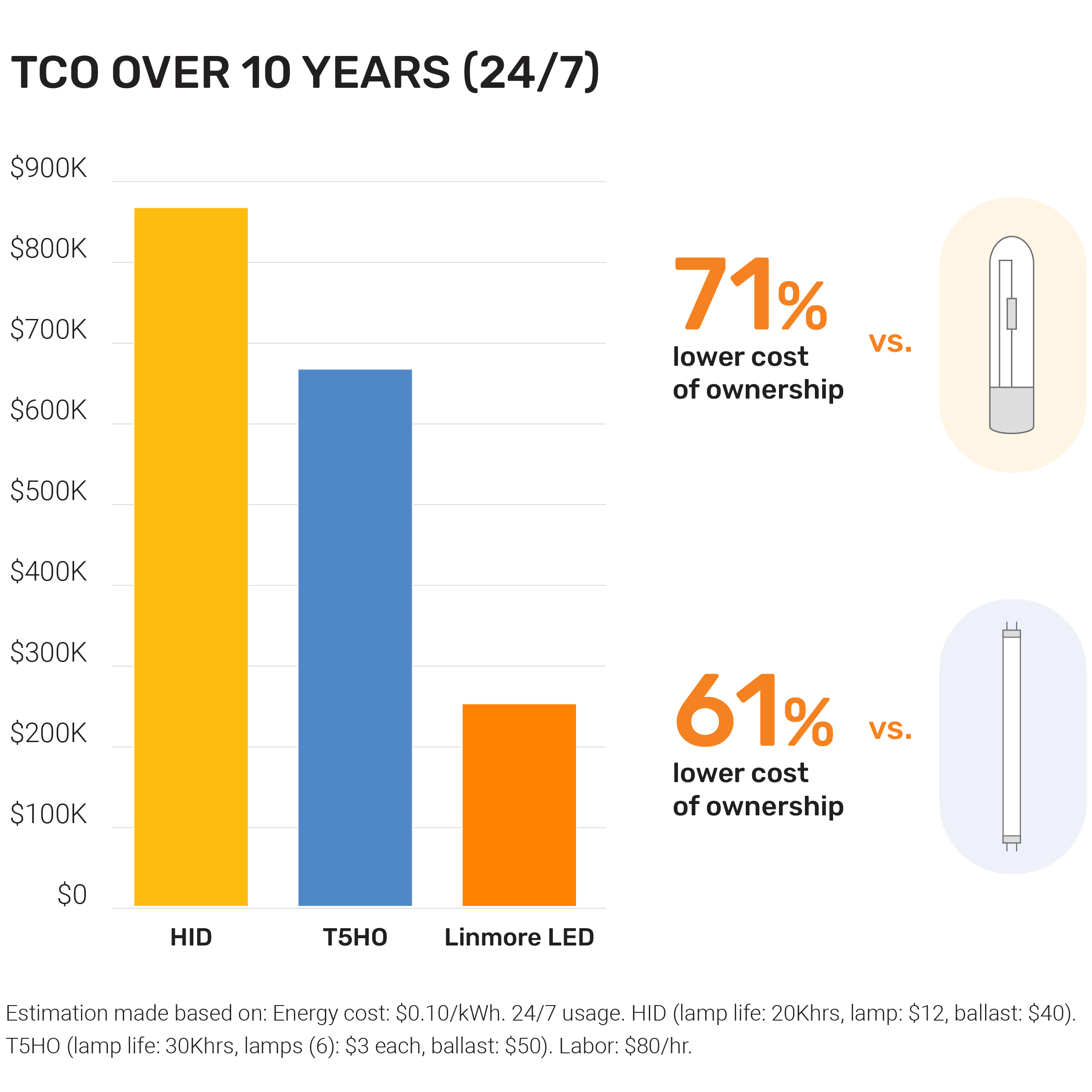

High quality LED lighting creates safer more productive facilities. Our highly efficient LED fixtures deliver high lighting levels at all temperature conditions, producing significantly less heat than others, so less refrigeration is needed to maintain the desired temperature conditions.

Higher Productivity

When optimal illuminance levels are met, workers experience better visibility and higher concentration, increasing their accuracy and work speed.

Safer Machine Operation

Certain food processing tasks involve the use of sharp utensils such as knives, grinders and slicing machines; increased light levels with low glare and adequate uniformity are required to prevent accidents.

Accident Prevention

In freezer areas, walking or driving forklift trucks in wet or icy conditions represent a high risk if employees cannot see the floor properly due to inadequate lighting.