March 9, 2021

How to illuminate a hangar

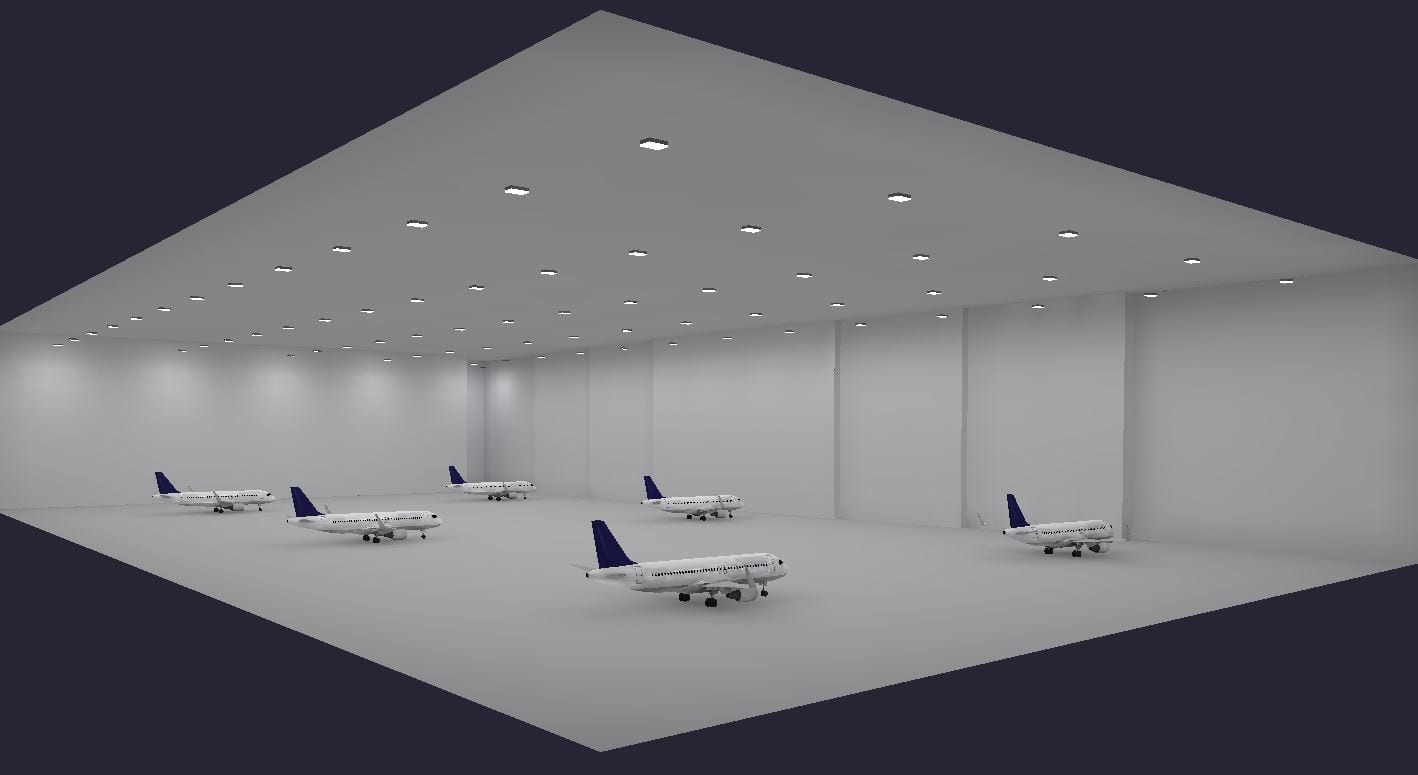

After designing aircraft hangars for a variety of clients, ranging in size from small, corporate facilities to massive projects for the U.S. Air Force, we have found they all have very similar lighting design challenges. In order to meet the typical hangar lighting requirements, here are my recommendations on how to illuminate a hangar.

Even illumination

Much of the maintenance work is completed on the underside of the plane. There needs to be plenty of light with as few shadows as possible. The vertical surfaces of the aircraft are regularly inspected for damage. There must be sufficient light even at those higher levels to detect and repair damage.

Overall, the lighting needs to be strategically placed, often using angled optics and higher-than-typical fixture density, compensating for the reflectances of each of the interior finishes.

Finishes

Ideally the floors, walls and ceilings are all finished in a highly reflective, flat sheen, such as white epoxy. This finish palette minimizes shadowing of light and dark areas throughout the space. This is critical for both the pilots and the maintenance teams, preventing accidents and increasing their ability to see small objects.

When illuminating hangars, the use of reflective finishes often reduces the number and intensity of the fixtures required, saving the client both construction and energy costs. The finishes of your hangar should be considered when determining the best fixture for your upgrade.

Glare

We want to avoid glare or bright points of light as much as possible in a hangar filled with reflective components. Glare can blind pilots as they are maneuvering the aircraft within the hangar. It can also obscure critical defects when maintenance teams are inspecting aircraft for structural defects. Excessive glare also increases worker fatigue.

We can reduce glare through use of frosted or prismatic lenses, indirect lighting and strategic placement of fixtures within the space.

Color rendition

Airplane maintenance requires frequent visual inspections. In order to see the multiple colors of wiring and make proper connections in an aircraft, it is critical that the lighting is not only bright, but has the highest available color rendering or CRI (Color Rendering Index). We recommend to use LED fixtures with a minimum CRI of 80 for illuminating hangars.

Heavy-duty and weather resistant

Depending on the location, hangar temperatures can range from freezing cold to extreme heat and are often poorly insulated. These temperature variances can dramatically reduce the life expectancy and light output of LED fixtures. Compounding this, when the large bay doors are open, rain, snow, dust and high winds can wreak havoc on the lighting system.

To combat these elements, we often recommend a wet, dust-resistant, high ambient temperature-rated fixture installed with a heavy-duty mounting system.

Life and energy consumption

As we all know, LEDs offer an extremely energy-efficient lighting option. Did you know that efficiency and fixture life can be increased even more by a well-designed control system of the lighting? We recommend motion detectors, timers, dimmers or even remote options.

Hangars doubling as event spaces

By specifying LED lighting controlled through dimmers, the hangar can double as an event space to rent or for corporate functions. The Kansas City Downtown Airport has successfully done this for number of fundraisers and social events. The overhead lighting is dimmed down and portable colored LEDs highlight the walls and aircraft creating a dramatic event space!

When you are ready to upgrade your hangar lighting, make sure you consider these things. If you have questions or have a hangar project you would like us to review, please contact us!