March 9, 2021

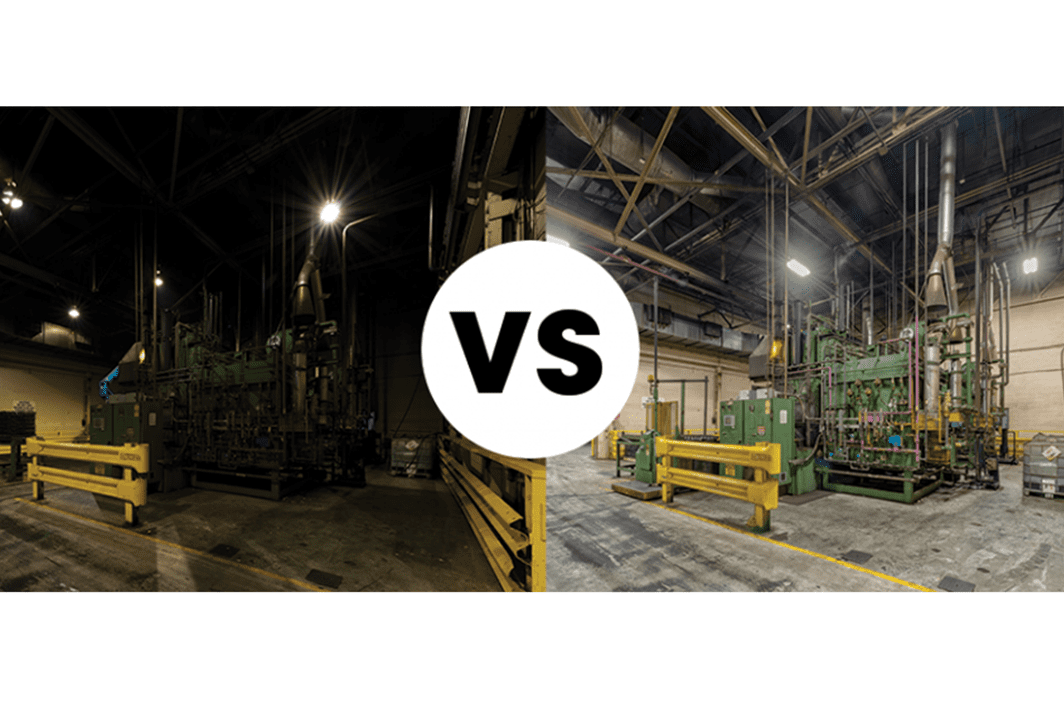

How to choose the right lumen output when replacing conventional light fixtures

Choosing the right lumen output of an LED fixture to replace conventional light sources isn’t a simple formula. There are many things to consider, including initial lumen output, optical efficiency and lumen maintenance.

Let’s talk initial lumens.

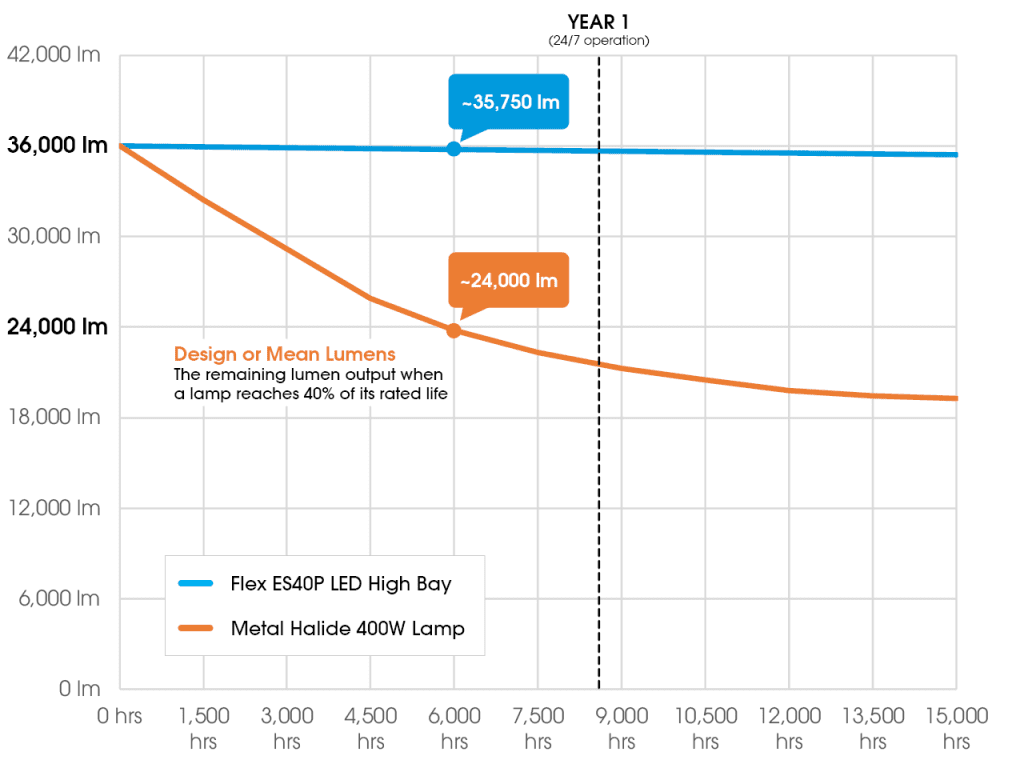

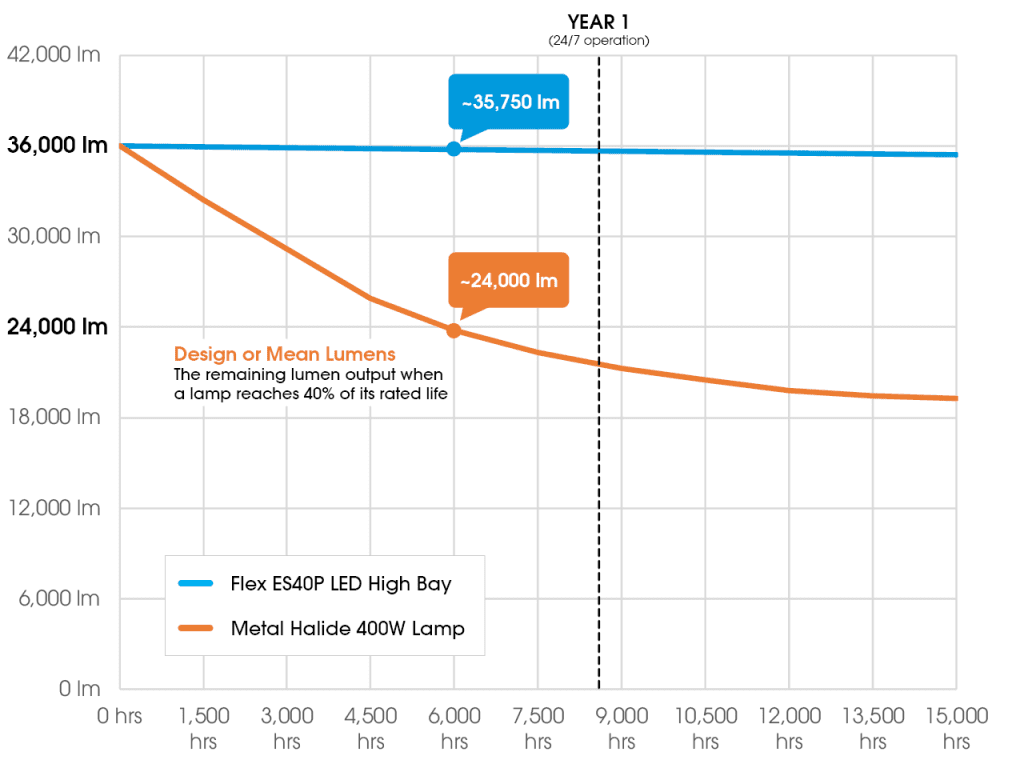

When designing a space with traditional light sources, the illumination levels are based on design or mean lumens, not initial lumens. This information is usually shared in the spec sheet of the lamp and / or fixture manufacturer. The average 400W metal halide lamp has an initial lumen output of 36,000 and a mean lumen output of 24,000. Based on this, you may think replacing a 400W MH with a 24,000 lumen LED fixture is the answer, but maybe not…just wait.

WHAT ARE DESIGN OR MEAN LUMENS?

Design or mean lumens, are typically measured at 40% of lamp life for conventional light sources. Example: 400W MH = 36,000 initial lumens and 24,000 mean lumens. With a 15,000-hour rated life, the lumen output at 6,000 hours is approximately 24,000 lumens, and at 15,000 hours the lumen output is approximately 18,000.

Consider this: for a 400W Metal Halide lamp with a 15,000-hour rated life, 24,000 lumens occur after just one year of 24/7 operation which is typical in industrial environments. But what happens between year two and three? Light drops to 17,000 lumens at the end of year two. Now you’re looking at a 17,000 lumen LED. Perhaps… but consider how often end-users change their lamps. Most wait until lamps burn out or are too dim before changing them.

Lumens aren’t the only factor to consider when illuminating working environments. The needs of the end-user, the layout and use of the space, and the IES recommended light levels are all key factors when selecting a replacement.

Now, let’s talk optical efficiency.

Conventional light fixtures have tubular, elliptical or bulb-shaped lamps emitting light in all directions and a reflector or refractor to direct the light where it is needed. This leads to significant light losses, which vary depending on the design and quality of the reflectors – and how clean they are. The ratio of lumens produced by the light source versus the amount of light the fixture actually delivers is called optical efficiency.

So, what is the typical optical efficiency of a 400W MH fixture? The average is somewhere between 65% and 80%. If we take a 400W MH at its mean lumen output of 24,000 lumens and apply an optical efficiency factor of 70%, we get 16,800 lumens.

WHAT IS THE OPTICAL EFFICIENCY OF A FIXTURE?

The amount of light produced compared to the amount of light leaving the fixture. Due to the shape of the conventional lamps, light is sent in every direction, requiring a reflector to bounce the light where is needed. Depending on the type of reflector, there can be considerable light losses. Average 400W metal halide high bays can have an optical efficiency of 70%. LEDs have a more directional light and for most high bay applications fixtures have lenses instead of reflectors, achieving optical efficiencies in the 90% range.

METAL HALIDE

LED

Finally, let’s review LED life vs. measured life.

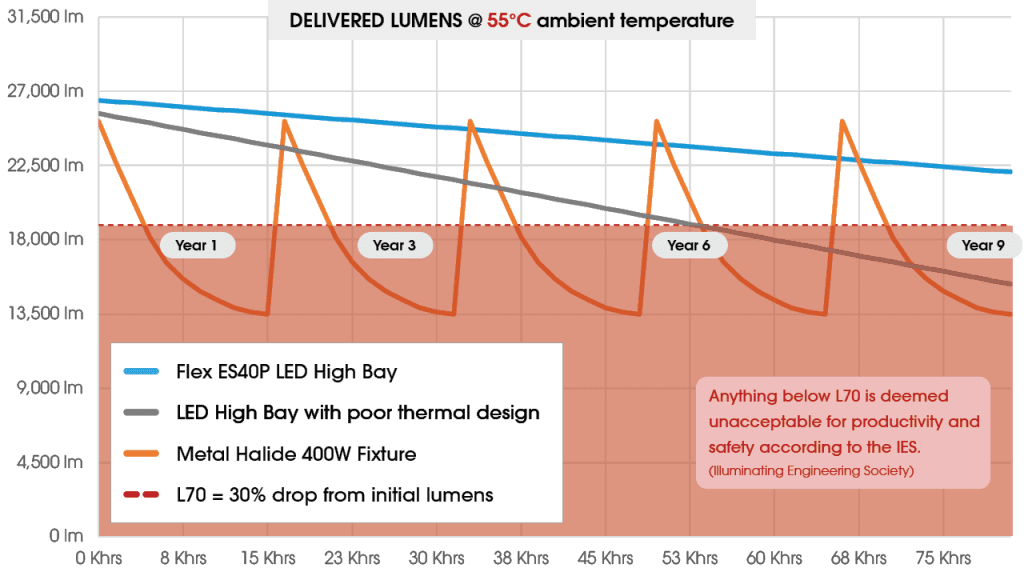

LED life isn’t measured in the same way as conventional light sources. For LED’s we project when the initial lumen output will drop 30%. This is called L70, referring to the fixture delivering 70% of the initial lumen output. This is when the IES (Illuminating Engineering Society) recommends replacing the fixture, as anything below L70 is deemed unacceptable for productivity and safety. L70 is calculated with an algorithm based on initial data and extrapolations. The projected L70 hours varies greatly depending on the design of the fixture and the environment in which it operates – it’s not the same in an office at 25C (77F) as a steel factory at 55C (131F). The range can be anywhere from 50,000 to over 300,000 hours. If you select a fixture with a lower projected L70, you will need one with a much higher initial lumen output to compensate for the steep drop, perhaps 24,000 lumens. A high-quality LED fixture with a longer L70 at higher ambient temperatures might allow you to choose a 17,000-lumen model which is more energy-efficient and costs less.

So, how do we decide? We need to consider the ambient temperature in the application, lumen maintenance, efficiency, needs of the client and IES-recommended light levels.

There’s no simple formula as every fixture has its unique characteristics, and the difference in quality ranges greatly when it comes to LED. We also need to ask, when do we need that specific light level? 400W MH fixtures range from 25,000 delivered lumens down to 13,000 lumens at end of life (15,000 to 20,000 hours depending on the brand of the included lamp). Lower-quality LED fixtures typically see a severe drop in light output based on ambient temperature due to their poor thermal design. It is normal to see them lose 50% of their initial lumen output at moderate temperatures after just a few years of use. So, the question is: how long do you need a certain light level? Day 1? Year 1? Or year 10? A well-designed LED fixture with a long L70 should provide years of low maintenance and steady light levels.

WHAT IS MEASURED LIFE?

Traditional source life is based on the hours it takes for 50% of the lamps to burn out, so if half of the lamps burn out at 20,000 hours, that’s your life. LED is measured using L70, the hours it takes for the lumen output to drop by 30%. Neither of these methods account for ballast or driver life, that’s an entirely different discussion.

When it’s time to replace your traditional light fixtures, don’t assume anything. You will need to research the lumen output, the efficiency and the L70 life of the specific fixtures you are considering. Look or ask for performance data at the ambient temperature of your facility. Always compare apples to apples and don’t fall prey to false advertising.

Adam Risemberg

ESCO Development Manager